In 2012, it was estimated that approximately 260 million direct composite restorations are performed on average per year worldwide. It is clear that in 2019 this figure was significantly higher. At the same time, it should be understood that the materials that dentists use in their practice, such as light-curing composites, adhesives and composite cements, in fact, are specific “semi-finished products”, because the success of their use largely depends on how adequately the process of their polymerization will be carried out. .

The polymerization lamp (PL) has taken one of the most important places in the daily appointment of a dentist. At the same time, many dentists still do not understand exactly how the PL works and what parameters of the lamp most affect its effectiveness. This leads to the fact that doctors buy the cheapest analogues, not caring about the indicators of the radiation spectrum, its power, propagation and beam profile. In this article, we will discuss all of the above criteria so that dentists can avoid key mistakes when buying the next PL.

Cure lamps are medical devices

In most countries, dental curing lamps are classified as medical devices and therefore must be properly registered and thoroughly cleaned before each new use. Nevertheless, the number of PL sellers on the Internet continues to grow, who do not care too much about the quality of the product they sell. And while at low prices a doctor can buy 10 budget PLs instead of one really high-quality one, we strongly recommend avoiding the purchase of devices that do not meet registration requirements, since in the worst cases they can harm the patient and cause various litigation.

Emission of light-emitting diode (LED) curing lamps

Small, battery-powered, energy-saving LED curing lamps currently dominate the market. For many clinicians, the first factor in choosing a lamp is its price, while the lamps themselves can differ significantly in terms of radiation parameters. Even with the availability of such information on the product box, doctors are often confused by the abundance of physical indicators, not understanding which of them is responsible for what. Manufacturers, on the other hand, often describe the advantages of the lamp in such a way that even with a great desire, an ordinary dentist will have to spend a lot of time and patience in order to master the necessary terminology.

However, the dentist should be able to navigate at least the following terms:

- radiant energy (measured in joules, corresponds to the radiation energy of the lamp);

- energy exposure (measured in joules per square centimeter, corresponds to the distribution of energy per unit area);

- radiant flux intensity (measured in watts, corresponds to energy per unit of time);

- energy luminosity (emissivity) (measured in milliwatts per square centimeter, corresponds to the intensity of radiation received by a certain surface area with a minimum distance between the radiation source and the surface on which it acts);

- surface radiation density (measured in milliwatts per square centimeter, corresponds to the intensity of radiation received by a certain area);

- radiation spectrum (measured in nanometers, corresponds to the wavelength of radiation;

- spectral radiation power (measured in milliwatts per nanometer, corresponds to the intensity radiation per nanometer);

- spectral radiant flux density (measured in milliwatts per square centimeter per nanometer, corresponding to the radiant flux density that a certain surface area receives at each nanometer of radiation length).

The relationship between lamp power, propagation of radiation and its intensity

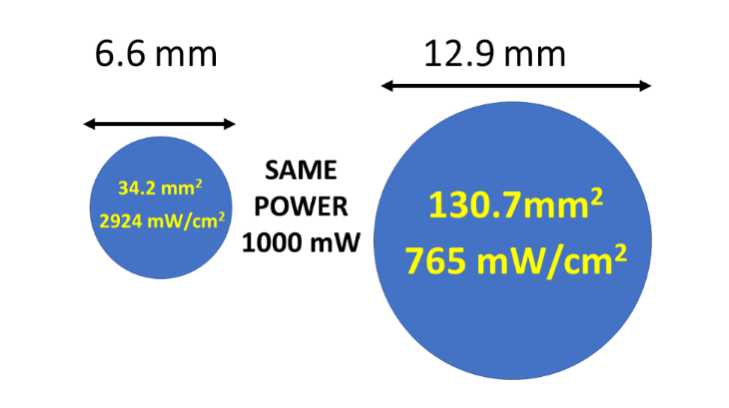

Photo 1 shows that by reducing the diameter of the paw tip, it is possible to achieve higher radiation intensities at a lower initial power. At first glance, many budget polymerization lamps are no different from expensive ones, but in fact, the tip diameter of such lamps is often 6-7 mm. In this case, the effective radiation diameter is not the outer diameter of the tip, but only corresponds to its area that actually emits the luminous flux. Most curing lamp tips are round in shape, hence the πr2 formula can be used to calculate the output cure and light level (mW/cm2). Thus, even small changes in the effective tip diameter will have a significant effect on area, intensity levels, and light levels. For example, a decrease in the effective diameter of the tip from 10 to 7 mm provokes an almost twofold decrease in the effective radiation area, which, in turn, justifies the need to double the power level to achieve the same radiation intensity.

Photo 1. If light guides of different diameters are characterized by the same power level, then their distribution indicator per unit area will differ markedly.

Distance effect

Increasing the distance from the top of the light guide to the surface of the composite reduces the level of radiation intensity acting on the composite material. This reduction is not inversely squared because in most cases the light beam produced by the lamp is collimated and focused. For certain lamps, the decrease in radiation intensity with increasing distance from the composite can be quite pronounced, while for other lamps, this effect remains not so noticeable, although influential. Considering that the average distance from the top of the lamp to the surface of the composite is 6-8 mm, manufacturers should indicate what parameters of radiation intensity are typical for their lamps at this distance. In addition, it would be good if manufacturers also indicated the distance at which the luminous flux intensity is halved compared to the situation when the distance between the lamp tip and the composite surface approaches 0 mm.

Fiber diameter and angle

Don't assume that lamps with larger tip diameters will help you cure larger areas. The effective size of a light guide is determined not by the outer diameter of the tip, but only by the diameter of the light beam emission. Therefore, for the polymerization of the entire restoration at once, it is necessary to compare the size of the restoration with the effective size of the light guide. Wide light guides (10-12 mm inner diameter) are effective for materials designed for volumetric demolition or in cases of MOD cavities. Narrow tips (6-8 mm inner diameter) are recommended for polymerization of small portions of material and restorations of the 5th class. Long light guides with an angle of 40–50° make it difficult to adequately position them in the area of distal restorations; instead, it is advisable to use analogs with an angle of 80–90° or lamps in which the LED emitter is located in a low-profile head.

Emission spectrum

The dentist must be sure that the curing lamp emits light at the wavelength required to activate the photoinitiator present in the composite. Previously, for the purpose of polymerization in dentistry, quartz tungsten-halogen lamps (QTH) were used, which are characterized by a wide spectrum of violet and blue light emission. This range was sufficient for the intended use of these lamps in dental practice, given the available spectral range. In contrast, single-peak LED lamps are characterized by a rather limited spectrum range (photo 2 A, B, C and D), which is adapted to the need for activation of camphorquinone (CQ), which is part of most photocomposite materials. This photoinitiator is activated by blue light with a maximum absorption level at a wavelength of 468 nm. However, a number of several other photoinitiators are often used in the structure of materials that are more rapidly responsive to light, such as trimethylbenzoyldiphenylphosphine oxide (TPO) and 1-phenyl-1,2-propanedione (PPD). These initiators are most sensitive to ultraviolet or violet light with wavelengths between 380 and 410 nm rather than up to 468 nm. Thus, conventional single-peak LED lamps, which simply do not emit light below 420 nm (photos 2A, B, C and D), simply cannot activate alternative photoinitiators used in the structure of dental composites.

Photo 2. Emission spectrum and power of eight different curing lamps. Notice how narrow the range is in pictures A-D and how wide it is in pictures E-H.

Consequently, some LED curing lamps such as Valo (Ultradent), Light 405 (GC America), Translux 2Wave (Kulzer) and Bluephase G4 (Ivoclar Vivadent) are now equipped with additional light guides with a lower violet wavelength, allowing them to achieve activation of a wide range of photoinitiators. The number and location of spectral emission peaks varies depending on the manufacturer, as well as on the total output power of the lamp. However, if the design of the polymerization lamp is not carefully designed, adding additional LED emitters with different wavelengths can adversely affect the uniformity of the light beam as a whole. This lack of homogeneity of the light beam can then affect both the radiation in the complex and the wavelength of the light beams that make up the main light beam. All this negatively affects the level of polymerization of the composite, the strength of the material, the stability of the color of the restoration and its wear resistance.

Influence of light beam uniformity

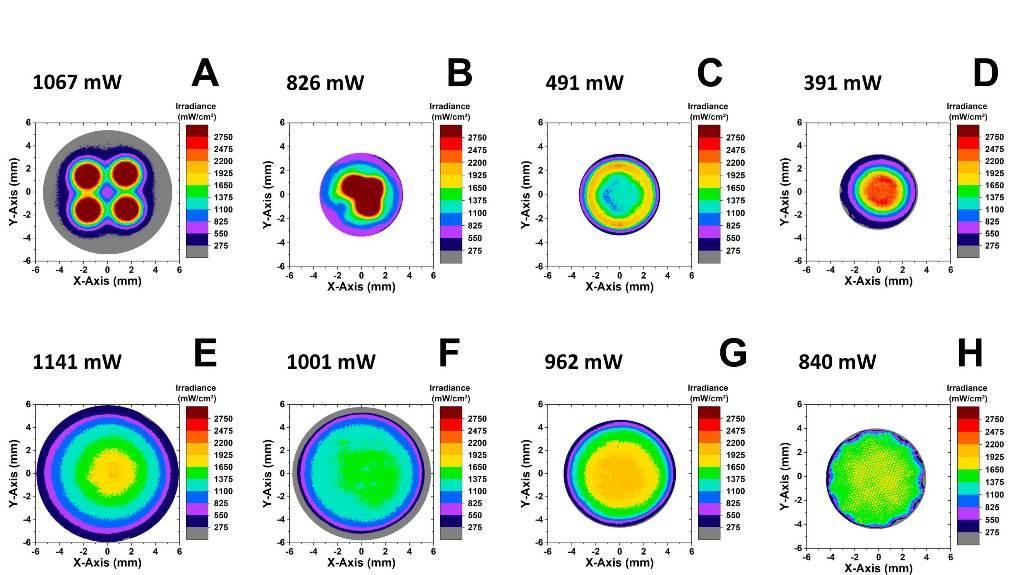

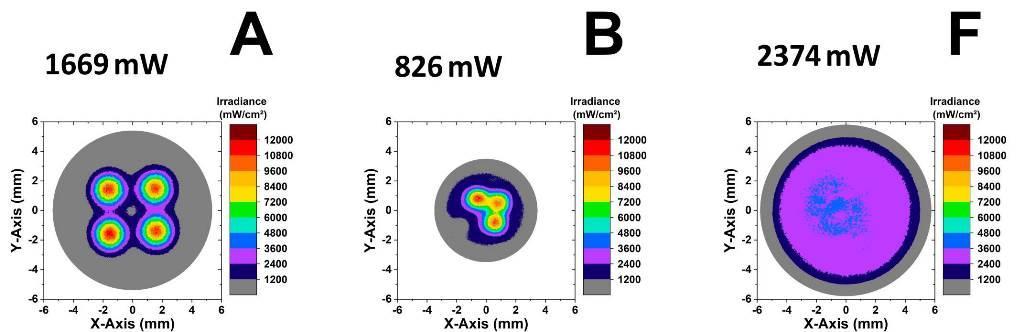

To study the light beam of polymerization lamps, digital cameras are often used to evaluate the uniformity of the light flux. Both two-dimensional and three-dimensional images of the radiation intensity recorded at the tip of the light guide confirmed the fact of its inhomogeneity during testing of different polymerization lamps. Therefore, the emission intensity and spectrum indicators must be interpreted with care, since they are used as parameters for evaluating the light beam at the output. In fact, these parameters demonstrate average values, which in no way take into account the unevenness of the light while at the tip of the light guide (photo 3). Given the fact that there are so-called hot spots at very high light intensity, a study was carried out in which three different curing lamps were set to a maximum intensity level of 12,000 mW/cm2 (photo 4).

Photo 3. Raw power and 2D beam profile of eight different lamps tuned to the same intensity level. Note the presence of hotspots in the cases of lamps A and B, which are well above the 2750 mW/cm2 intensities.

Photo 4. Power, average intensity and 2D profiles of the light beam when three different lamps were tuned to the initial parameters of 12000 mW/cm2. Despite the relatively low power in the case of lamp B (826 mW), the level of radiation intensity when using it reaches 2169 mV/cm2, which is argued by the smaller diameter of the tip. At the same time, the intensity in the case of the F lamp is much lower due to the wider tip diameter.

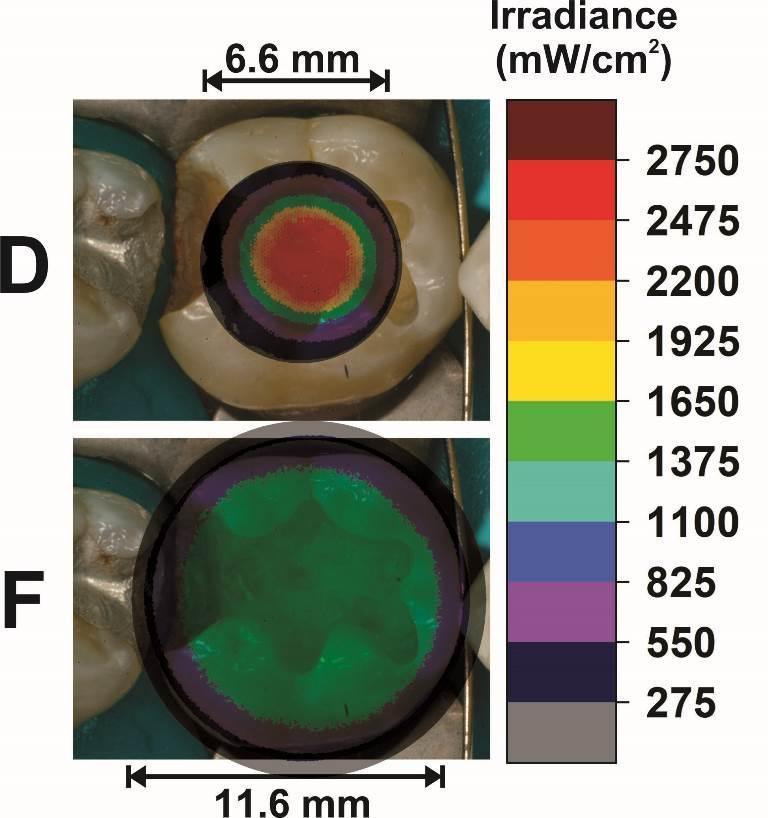

Photo 5. Two-dimensional beam profile at the top of narrow and wide fibers tuned to 2750 mW/cm2. The presence of hot spots in the case of the D lamp, and the uniformity of the light flux in the case of the F lamp.

Recommended parameters for curing lamps

In conclusion, when choosing a dental polymerization lamp, it is recommended to pay attention to the following parameters:

- certification by the relevant authorities for dental use;

- ergonomic design, suitable for both doctors with large and small hands;

- an easily accessible control interface that provides tactile and visual identification of settings;

- suitable angle of the light guide that allows for perpendicular positioning to the surface of the restoration, regardless of its polymerization;

- sealed lamp system, which allows it to be easily cleaned and optimally controlled for the possibility of bacterial contamination;

- the presence of barriers that limit the possibility of bacterial contamination, but do not compromise the effect of light emission;

- a wide spectrum of radiation, which allows the activation of a number of photoinitiators;

- wireless or wired character of the model;

- the ability to adjust the lamp in order to adapt to different clinical situations;

- simple charging with long battery life and low battery replacement costs;

- protective screen that blocks stray light and allows you to control the position of the light guide over the restoration;

- changeable effective polymerization diameter from large to small and vice versa to adapt to the required clinical conditions;

- the presence of “smart” polymerization functions that allow you to increase the polymerization time depending on the distance of the lamp from the restoration surface.

Tips for improving clinical success when using polymerization lamps:

- always check the curing lamp for the possibility of curing a particular composite: read the recommendations of the composite manufacturer and check the curing of both the lightest and darkest shades of the composite, while controlling the curing time and distance to the surface of the material;

- on-the-job training: periodically review with staff the methods of polymerization of materials, approaches to cleaning and maintenance of polymerization lamps; regardless of the light beam parameters used, the clinical method of applying the lamp is of key importance; during polymerization, it is recommended to always control the position of the fiber;

- ensuring a clean state of the light guide: after the end of the procedure, always clean the light and protective glass; periodically you can check the level of radiation at the output of the light using a radiometer;

- ensuring lamp heating control: radiation energy (J) is its power (W) multiplied by time (seconds); thus, powerful illumination with high radiation intensity can lead to significant tissue heating, which can cause some damage to the structures of the oral cavity; the heating effect can be minimized by exposing the tooth to a light stream of air every 3-5 seconds of polymerization;

- safety for the clinician's eyes: blue light can potentially disrupt the circadian rhythm or accelerate retinal aging, so overexposure to the light beam should be minimized with a suitable orange visor or orange goggles so that the operator can safely observe and at the same time control the position of the light guide.

Conclusions

- Effective light guide area, output power, intensity, spectrum and beam profile vary considerably between dental curing lamps.

- The indicator of radiation intensity is not sufficient to describe all the advantages/disadvantages of a polymerization lamp. Even if the average light guide intensity is ~2000 mW/cm2, some lamps show hot spots with very high intensities exceeding 12000 mW/cm2.

- Slight changes in fiber diameter are associated with large changes in performance radiation intensity.

Authors:

Richard B. Price, BDS, DDS, MS, PhD

Gordon Christensen, DDS, MSD, PhD

Stella Braga, DDS < /p> Buy on the market  Ultradent VALO Cordless Wireless Light Curing Lamp from Rs. 119 500 lampu-af479ef.png” class=”img-polaroid” alt=”How to choose a curing lamp?7″ /> Ultradent VALO Photopolymerization LED lamp, wired 175 249 r.All prices

Ultradent VALO Cordless Wireless Light Curing Lamp from Rs. 119 500 lampu-af479ef.png” class=”img-polaroid” alt=”How to choose a curing lamp?7″ /> Ultradent VALO Photopolymerization LED lamp, wired 175 249 r.All prices  Ivoclar Vivadent Bluephase 20 Wireless LED polymerization lamp

Ivoclar Vivadent Bluephase 20 Wireless LED polymerization lamp  Ivoclar Vivadent Bluephase Style Wireless LED Curing Light from Rs. 72 500 -vybirat-polimerizacionnuju-lampu-67ddb11.png” class=”img-polaroid” alt=”How to choose a polymerization lamp?10″ /> Ivoclar Vivadent Bluephase Wireless LED polymerization lamp from 26 819

Ivoclar Vivadent Bluephase Style Wireless LED Curing Light from Rs. 72 500 -vybirat-polimerizacionnuju-lampu-67ddb11.png” class=”img-polaroid” alt=”How to choose a polymerization lamp?10″ /> Ivoclar Vivadent Bluephase Wireless LED polymerization lamp from 26 819  Ivoclar Vivadent Bluephase C8 Curing Lamp

Ivoclar Vivadent Bluephase C8 Curing Lamp